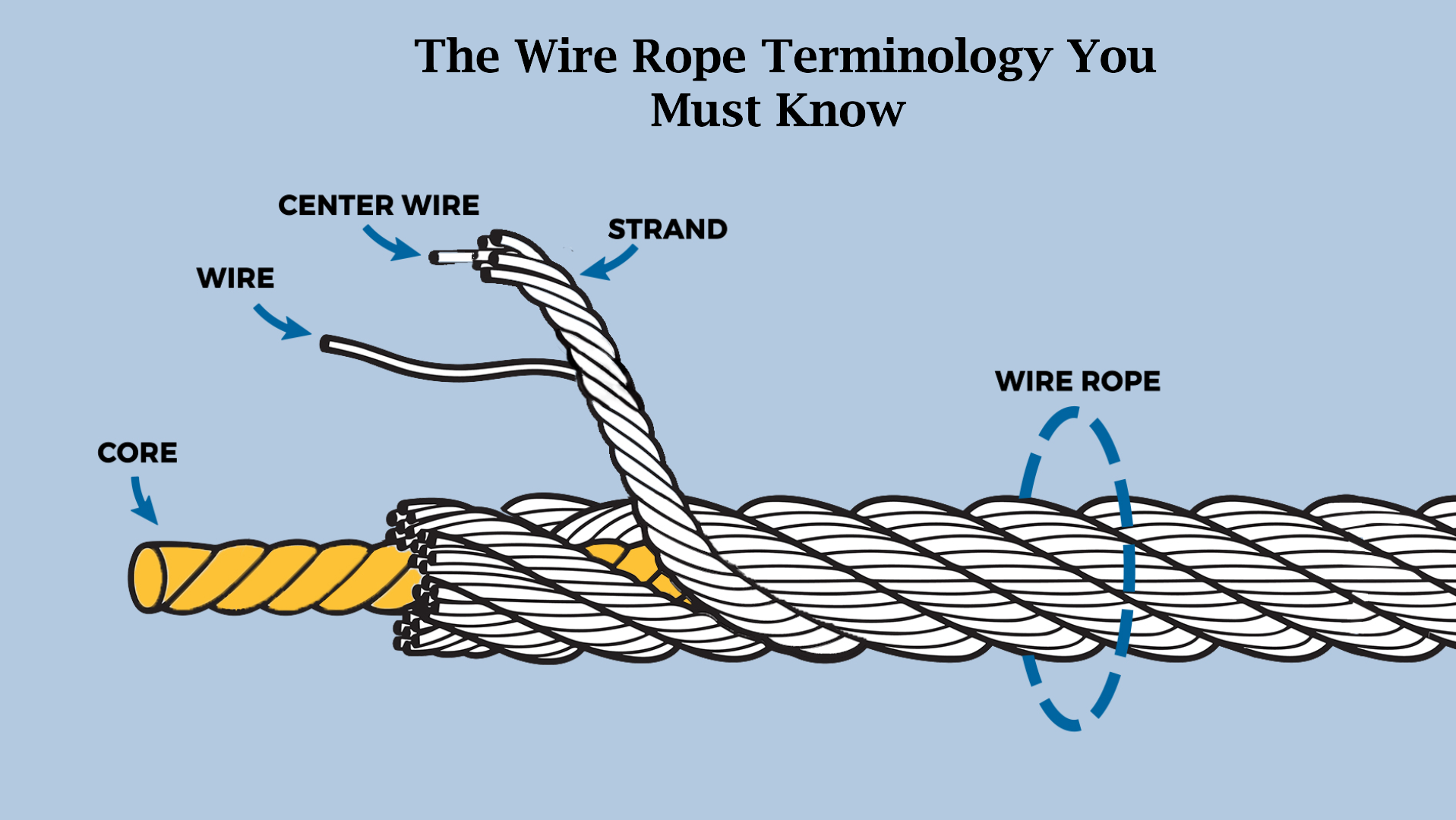

The Wire Rope Terminology You Must Know

Wire ropes are crucial components in various industries, including

construction, mining, and maritime operations. Understanding the terminology

associated with wire ropes is essential for ensuring safety and their efficient usage. One fundamental term is

"lay," which refers to the direction of the twist of wires in the

rope, categorized as either right-hand or left-hand lay. "Core"

signifies the central support structure of the wire rope, which can be composed

of fiber, wire strand, or an independent wire rope core (IWRC). Another vital

term is "construction," indicating the arrangement of wires and

strands within the rope, such as a 6x19 or 7x7 configuration, denoting the

number of strands and wires per strand. "Breaking strength" denotes

the maximum load a wire rope can withstand before failure, crucial for

determining its suitability for specific applications. Familiarity with these

and other wire rope terminologies is indispensable for professionals working with

these materials, ensuring safe and effective operations across various

industries.

Do wire ropes play a major role in

your business? Heavy-duty steel ropes are designed with specific standards to

meet the requirements of the most demanding applications.

In addition to these, you may come

across numerous other terms when dealing with wire ropes in day-to-day

industrial activities. Below are some of the most commonly used terms to denote

various components of a wire rope:

Wire: A single circular shaped metal of continuous length made from cold

drawn rod.

Strands: It is an element of wire rope consisting of an assembly of

several wires of appropriate shapes and dimensions spun helically in one or

multiple layers.

Core: The core is the foundation of a wire rope. It is an axial member

of rope about which strands are laid. These include Steel core (IWRC, WSC) and

Fibre core (PP, Sisal), combination of steel and fiber cores, and Solid Poly

core.

Rope: Fiber or steel strands are used to construct ropes, which are

then bunched together to form a core surrounded by strands and twisted cores.

Construction: Design of wire rope including no. of strands, number of wires per

strand, and arrangement of wires in each strands. Strand construction in the

wire rope can affect how it handles fatigue, abrasion, crushing, and other

applications.

Some common

construction types are as follows-

●

Seale: The larger outer

wires wrap around a layer of the same number of inner wires, which surround a

core. It is termed as “S”.

●

Filler: - In a 'filler wire' construction, small wires

are placed between larger ones to provide crushing resistance. It is termed as “F” or “FW”

●

Warrington: The outer layer

is made up of wires that alternate between large and small diameters, leading

to excellent flexibility. It is termed as “W”.

●

Combination: Combination

strands can be constructed using any combination of two or more of the patterns

listed above. Eg. Warrington-Seale (WS), Seale Filler (SF), Seale Warrington

Seale (SWS)

●

Single layer: - In single-layer construction, Strands

are made up with one center wire covered with no. of wires in one layer.

●

Multilayer

Construction: - In this type of construction, strands are made up with an

arrangement of multiple layers of different no. of wires of the same size on

each layer.

Lay direction: The direction of rope lay is determined by the direction of

individual strands within the rope that are twisted around the core, and the

direction of the wires within the strands that are twisted around the core. The

direction of rope lay is also referred to using the letters S and Z. By placing

the letters over the rope, the left-hand lay becomes S and the right-hand lay

becomes Z. Also Direction of wires in the strand is specified with a small

letter/case whereas the direction of strands in a rope is specified with

capital letter/case. Eg. RHO rope has strand direction in right hand side and

wires of strands are twisted in left hand side so RHO lay can be termed as “sZ”

and similarly for RHLL lay rope it is termed as “zZ”.

Bharat Wire Ropes

manufactures a wide range of steel wire ropes, spiral strands & slings,

catering to a large number of industries from Oil & Gas, Shipping,

Elevators, Cranes, Mining, Forestry, Fishing, Construction & Ropeways.

Contact us today to learn how our steel wire ropes can create

value for your organization.

Learn more about our products, company & our journey of excellence by visiting our website: https://www.bharatwireropes.com/

For all questions or inquiries from India email us on

domestic@bharatwireropes.com

For all questions or

inquiries from outside India email us on exports@bharatwireropes.com

You can also get in touch

with us by messaging us on LinkedIn- https://www.linkedin.com/company/bharatwireropes/