Unveiling the Strength and Versatility of Compacted Ropes: Explore Bharat Wire Ropes' Solutions

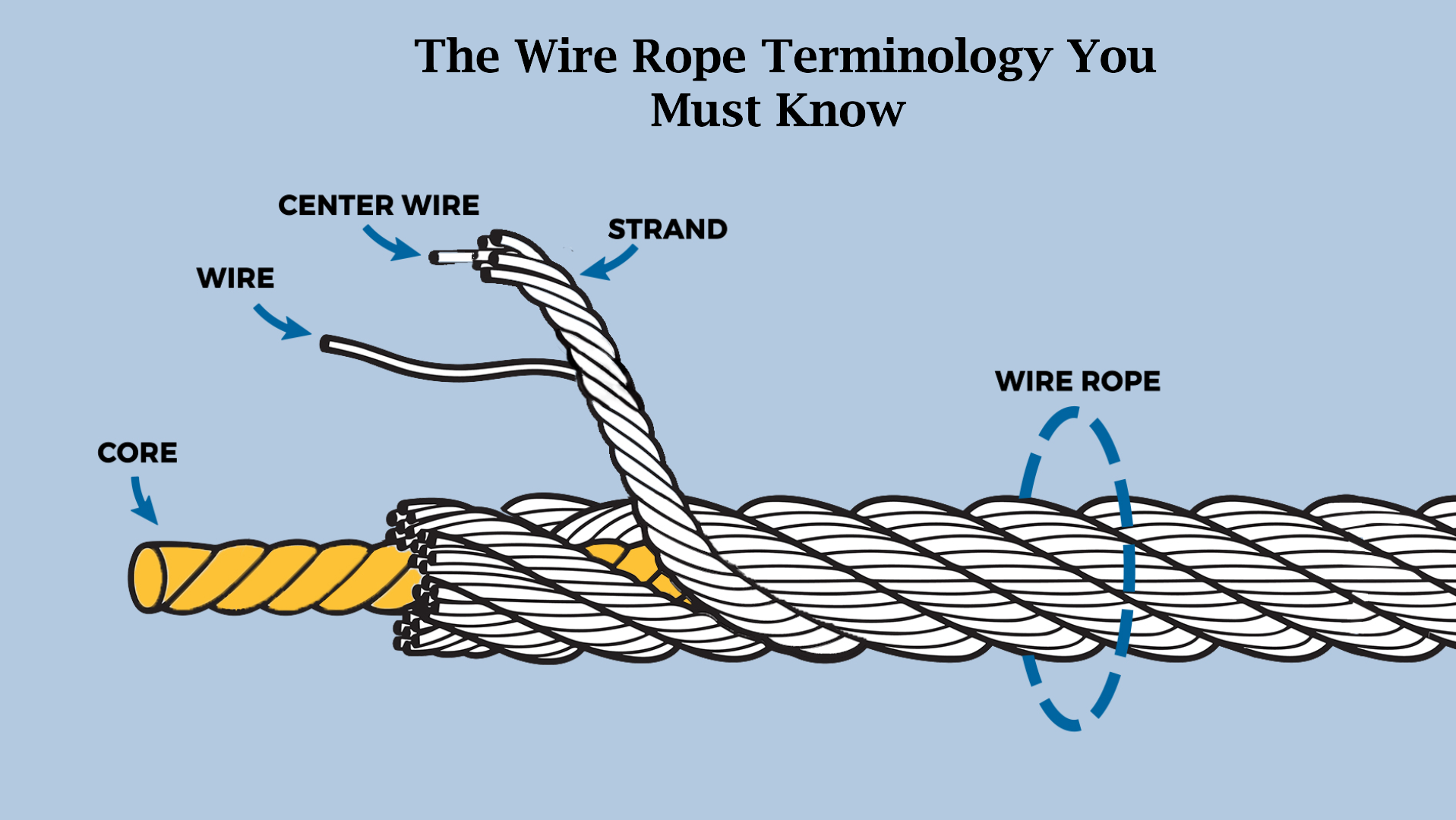

Compacted wire ropes are a type of steel wire rope where the

individual strands are compacted to create a smoother, more circular

cross-sectional shape. In compacted wire ropes, the strands undergo additional

processing to compact them, thereby reducing the gaps and spaces between them.

Compacted wire ropes are engineered to undergo a specialized

compacting process, resulting in a smooth and more efficient structure. In this

article, we explore the advantages and applications of compacted ropes and shed

light on why they have become preferred choices in many sectors.

Understanding Compacted Ropes:

Compacted wire ropes are made using a specialized process to compress the individual wire rope strands. The process involves running the strands through a Roller compaction unit that applies pressure to the strand, reducing its diameter and increasing its density.

This enhances the rope's strength, and abrasion resistance

and reduces the risk of internal & external damage. Compacted wire ropes are

commonly used in heavy-duty applications, such as maritime, construction, and

industrial sectors, where superior performance and durability are required.

Cranes and Lifting

Equipment: Compacted wire ropes are employed in cranes and various lifting

equipment where their high breaking loads and fatigue resistance make them

essential for carrying out lifting and rigging tasks effectively.

Increased Strength

and Fatigue Resistance: The compacting process imparts a higher level of

structural integrity to the rope, making it more robust and capable of

withstanding heavy loads and continuous use. This enhanced strength also

improves the rope's resistance to fatigue, allowing it to endure repetitive

stress and strain without premature failure.

Flexibility:

Despite their increased density, compacted wire ropes maintain their flexibility.

This characteristic is of particular importance in applications where ropes

need to navigate complex paths or pulleys, as it ensures smooth handling and

reduced wear.

Improved Resistance

to Crushing and Abrasion: The smooth surface of compacted wire ropes makes them

more resistant to external forces like crushing and abrasion. This property is

valuable in demanding environments where ropes are exposed to harsh conditions

and rough surfaces.

Extended Service

Life: Due to their increased strength, fatigue resistance, and better

protection against external factors, compacted ropes tend to have a longer

service life compared to standard wire ropes.

BWR provides all ranges of compacted wire ropes that would suit your requirements.

https://www.bharatwireropes.com/wire-ropes