Important rules to follow during wire rope inspection

Introduction:

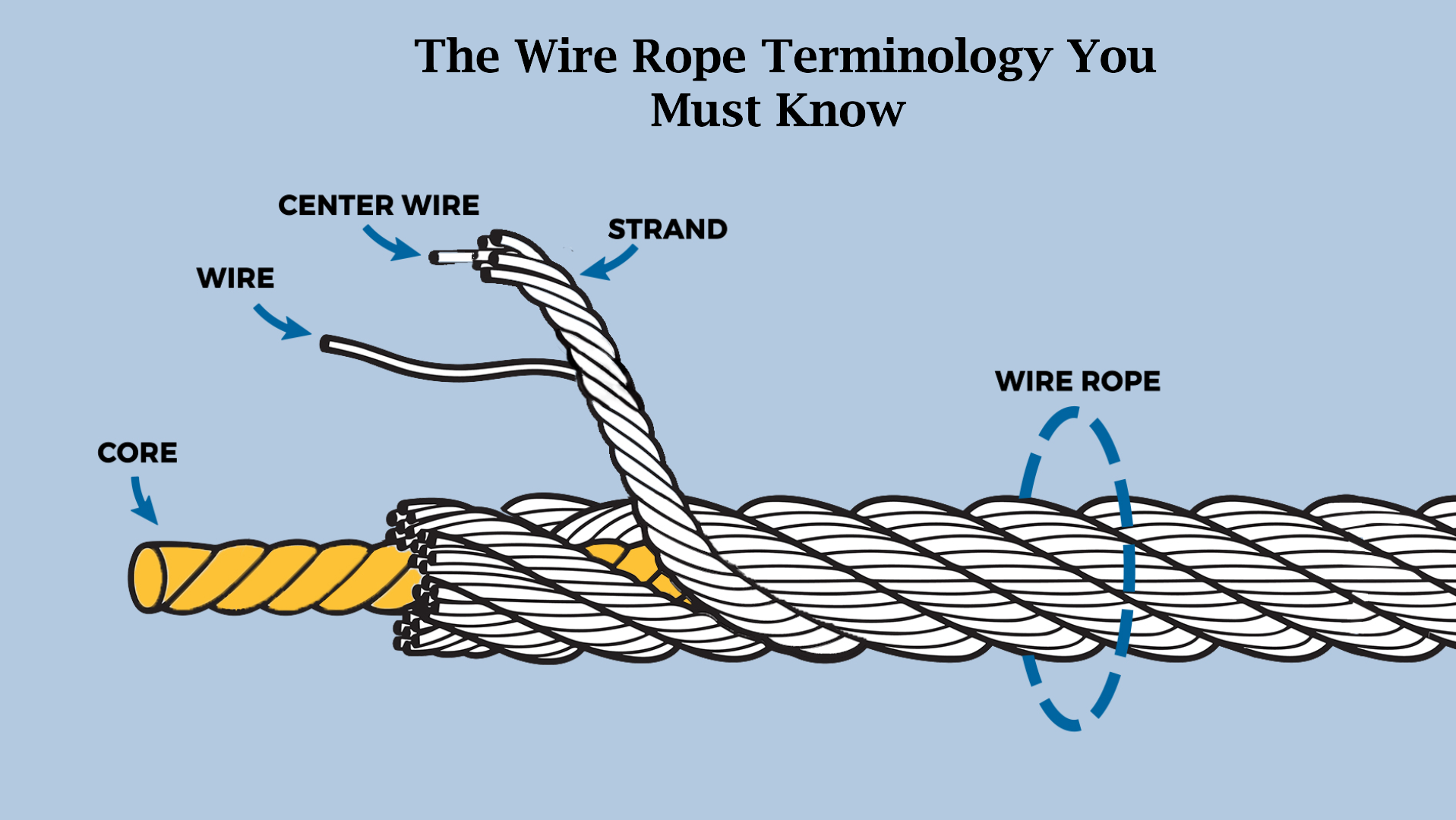

Wire ropes play a crucial role in various industries, serving as a lifeline for lifting, towing, and supporting heavy loads. As a critical component in many applications, it is imperative to prioritize the regular inspection of wire ropes to ensure their integrity and prevent potential accidents. Bharat Wire Ropes, a leading steel wire rope manufacturer, emphasizes the importance of adhering to specific guidelines for wire rope inspection to guarantee safety and reliability.

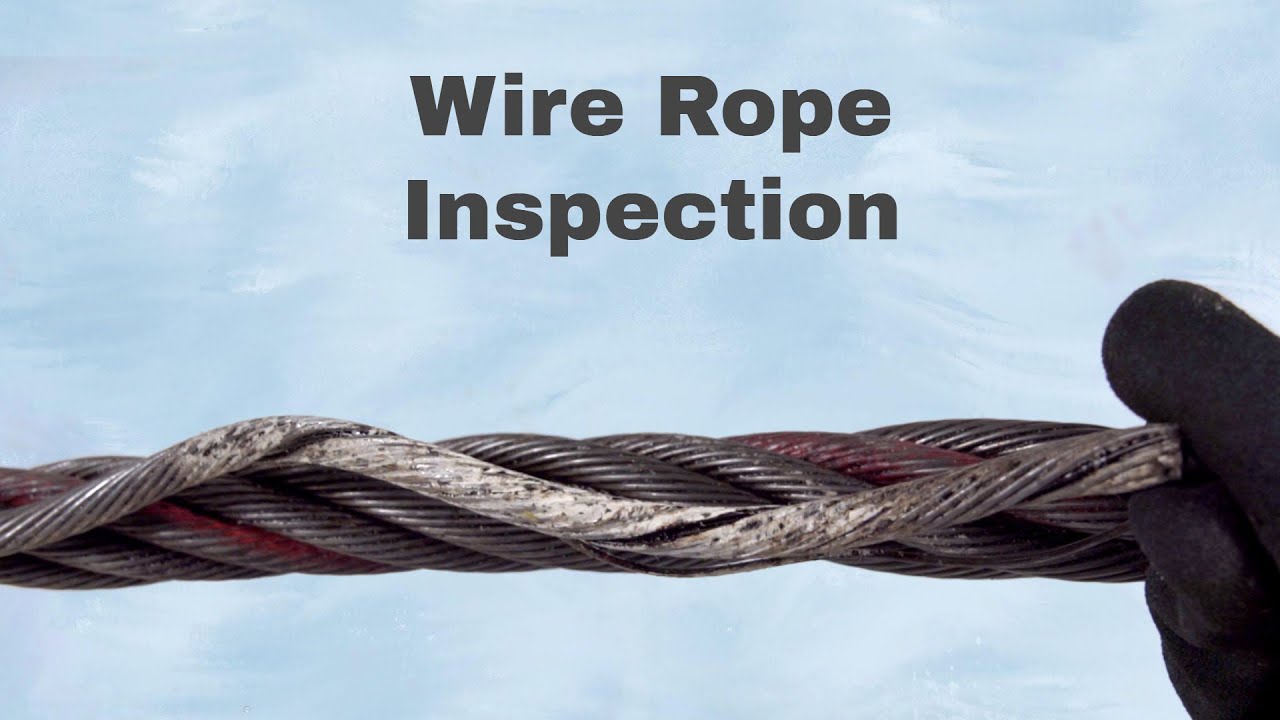

Establishing a routine inspection

schedule is fundamental to detecting potential issues early on. BWR recommends

regular visual inspections by trained personnel to identify visible signs of

wear, corrosion, or damage. This proactive approach helps in addressing

concerns before they escalate into major problems.

Ultrasonic Testing:

To

complement visual inspections BWR recommends incorporating advanced techniques

like ultrasonic testing. This non-destructive testing method can identify

internal flaws and degradation not visible to the naked eye, providing a more

comprehensive assessment of the wire rope's condition.

Understanding Load Limits:

Knowing the load limits of wire

ropes is essential to prevent overloading, a leading cause of wire rope

failure. Bharat Wire Ropes emphasizes the importance of following the

manufacturer's recommendations regarding load capacity. Understanding and

adhering to these limits ensures the longevity and safety of the wire ropes in

various applications.

Proper Storage and Handling:

BWR underscores the significance

of proper storage and handling to prevent damage to the ropes before they are

even put into service. Wire ropes should be stored in a clean, dry environment,

away from corrosive materials, and handled with care during transportation and

installation.

Thorough Lubrication:

Regular lubrication is crucial

for maintaining the flexibility and durability of wire ropes. Bharat Wire Ropes

recommends using the appropriate lubricants and following a consistent

lubrication schedule to reduce friction, corrosion, and wear, ultimately

extending the service life of the wire ropes.

Environmental Considerations:

The operating environment greatly

impacts the lifespan of wire ropes. We advise assessing the environmental

conditions, such as temperature, humidity, and exposure to chemicals, to

determine the appropriate type of wire rope and maintenance requirements.

Record Keeping:

Maintaining detailed records of

wire rope inspections is crucial for tracking the history of each rope and identifying

patterns of wear or issues. At BWR, we keep comprehensive records, including

inspection dates, findings and any corrective actions taken.

Training and Certification:

Emphasizes the need for training

and certifying personnel responsible for wire rope inspection. Properly trained

individuals are better equipped to identify potential issues accurately,

ensuring a higher level of safety and reliability in operations.

Conclusion:

Adhering to these important guidelines for wire rope inspection suggested by Bharat Wire Ropes is essential for ensuring the safety, reliability, and longevity of wire ropes in various applications. By prioritizing routine inspections, understanding load limits, and implementing proper maintenance practices, industries can minimize the risk of accidents and downtime associated with wire rope failures. Remember, a well-maintained wire rope is a reliable asset that contributes to the overall efficiency and safety of lifting and hoisting operations.

Contact us today to

learn how our steel wire ropes can create value for your organization.

Learn more about our products, company & our

journey of excellence by visiting our website: https://www.bharatwireropes.com/

For all questions or

inquiries from India email us on domestic@bharatwireropes.com

For all questions or inquiries from

outside India email us on exports@bharatwireropes.com

You can also get in touch with us by

messaging us on LinkedIn- https://www.linkedin.com/company/bharatwireropes/